ESA and Metalysis Organised the First Grand Challenge Midterm Workshop • Nov 2020

On November 9 and 10, ESA together with Metalysis organised an online workshop part of the Grand Challenge launched last December.

The Metalysis – ESA Grand Challenge worth €500 000 and sponsored by UK’s Metalysis, will reward new miniaturised technology that will improve and enhance the Metalysis patented electrolytic process capable to extract oxygen and titanium from regolith found on other planets.

In order to win the Grand Challenge first prize or one of midterm prizes sponsored by the UK metallurgic company Metalysis, the competing teams are requested to provide the Evaluation panel with two deliverables:

At the end of Phase 1, a Project Report detailing the process to be implemented by the participants in order to develop the final Breadboard and its potential functioning;

At the end of Phase 2, the breadboard developed according to the requirements set forth in the Terms and Conditions and Final Project report based on the same structure as the one required for the Deliverable of Phase 1 including the user manual.

On November 9 and 10, ESA together with Metalysis organised an online workshop part of the Grand Challenge launched last December.

The Metalysis – ESA Grand Challenge worth €500 000 and sponsored by UK’s Metalysis, will reward new miniaturised technology that will improve and enhance the Metalysis patented electrolytic process capable to extract oxygen and titanium from regolith found on other planets.

In order to win the Grand Challenge first prize or one of midterm prizes sponsored by the UK metallurgic company Metalysis, the competing teams are requested to provide the Evaluation panel with two deliverables:

At the end of Phase 1, a Project Report detailing the process to be implemented by the participants in order to develop the final Breadboard and its potential functioning;

At the end of Phase 2, the breadboard developed according to the requirements set forth in the Terms and Conditions and Final Project report based on the same structure as the one required for the Deliverable of Phase 1 including the user manual.

To accomplish Phase 1, the two Competing Teams had the chance to meet with the Evaluation Panel Members of the competition and with Metalysis, in order to better understand Metalysis technology and technical requirements.

This Mid-term workshop was an opportunity for:

- the competing teams to introduce themselves and ask all the questions they had at this stage of the competition

- ESA to recall the framework of the Grand Challenge and the importance to foster initiatives like this Grand Challenge that may be contribute to the strategic roadmap of the In situ resources utilisation (ISRU) future developments.

- Metalysis to present its processes and interact with the teams

Focus on the competing teams

The first team is a company called MALT. The MALT team is an interdisciplinary group including scientist and engineers with a background in spectroscopic solutions for applications such as heritage, biomedicine or space applications. The team members have participated as part of Spanish public research institutes and universities in the development of Raman and LIBS spectrometers for space applications such as RLS for ESA ExoMars or SuperCam for NASA Mars 2020 missions. Now, the aim is to incorporate this state-of-the-art technology for space to the civil society by spinning off to industrial applications. The participation of the company in the ESA Grand Challenge is a unique opportunity to demonstrate how laser-based spectroscopic techniques can be reliably used for specific applications, while also serving as a catalyser for the consolidation of this relatively young group of professionals into a long-term and auto-sufficient European-based company.

The second company, San Jorge Tecnológicas is led by Maria Pilar Del Alamo. Its active team includes engineers, scientists and technicians enjoying research and development of mechanisms, sensors, prototypes and new challenging technology and attracts cooperation from the best research institutions along Europe. In the last years they have successfully developed R&D projects for ESA, the European Commission 7th Framework Programme and Horizon 2020, Airbus, , OHB DARPA among others. Particularly, among the several inventions developed by this team, there are non-contact sensors, magnetomechanisms, devices for extreme environments and test benches. More information is available at www.sanjorgetecnologicas.com and www.magsoar.com

Focus on the ESA Grand Challenge

The ESA Grand Challenge aims at stimulating the creation of innovative space startup in Europe, boosting entrepreneurship through an ex-post competitive process. The competition is divided into two phases:

· Phase 1, which will potentially reward a team after the submission of a deliverable at the end of 2020. The Deliverable of Phase 1 is a Project Report detailing the process to be implemented by the Participants in order to develop the final Breadboard and its potential functioning.

· Phase 2, which will be over at the end of 2022 and will reward the winner after the submission of the final breadboard.

In Spring 2021, ESA and Metalysis will announce the winner of the first phase.

Focus on Metalysis

Metalysis in South Yorkshire, has spent more than a decade developing and scaling up its electrochemical technology; a process that converts refined oxides and ores directly into valuable metal alloy powders used in 3D printing for aerospace, automotive and high-value manufacturing.

Metalysis has been recently awarded European Space Agency (ESA) funding for its project titled, “The Metalysis FFC Process for Extra-Terrestrial Oxygen Production from ISRU,” which forms part of ESA’s Space Resources Strategy and carried out under the General Support Technology Programme of, and funded by, the European Space Agency. More information at the following links:

More articles of the category: Articles in news section

ESA Space Economy – Partnering with CERN to share best pract...

ESA Space Economy – Partnering with the OECD to develop inte...

Measuring the impacts of ESA programmes

Space Benefits for Earth - Preparing ESA Ministerial Council...

2nd Edition of the Workshop "Economics of Big Science" hoste...

First ever workshop on the “Economics of Big Science”

ESA Business Incubation Centres (ESA BICs) - Empowering spac...

ESA CM22 Economic Impact Report

ESA Science Programme: Empowering Europe’s Leadership in Cut...

ESA Benefit Case Studies – 100+ success stories of space for...

ESA Technology Market Assessments: understanding the foresee...

ESA pilots new framework to assess sustainability benefits a...

ESA launches new ITT to maximise sustainability benefits of...

Understanding the remarkable inspirational value of space ex...

Eurospace publishes the 2023 update of its facts & figures s...

Eurospace publishes the 2022 update of its facts & figures s...

Eurospace publishes the 2025 update of its facts & figures s...

ESA Space Economy – Understanding data on the space sector’s...

Impact of ESA R&D (Discovery) on Europe’s innovation and res...

ESPI publishes its annual report on the private investment i...

ESA Business Applications and Space Solutions Success Storie...

ESA HQ welcomes the 2nd Edition of ECSECO Space Economy Days

NASA Economic Impact Report 2024

Impact of ESA R&D (TDE/GSTP) on Europe’s innovation and rese...

ESA FutureEO - Foundation for Europe's innovation and resear...

ESA Report on the Space Economy 2025

NASA’s Economic Impact Report 2022

ESA Discovery - Understanding the impact of ESA early R&D on...

ESA FutureEO - Foundation for Europe's innovation and resear...

U.S. BEA publishes updates on the U.S. space economy’s contr...

Eurospace publishes the 2024 update of its facts & figures s...

Copernicus Summer Series - Wildfire Management in Greece

Copernicus Summer Series - Irrigation Detection & Mapping in...

Copernicus Summer Series - Oil Spill in the Mediterranean

Copernicus Summer Series - Golf Course monitoring in Italy

ESA Technology Transfer Success Story - A new perspective: s...

When space technologies improve day-to-day life on Earth

Exports: an imperative for the European Space Industry? - A...

ECSECO, the European Centre for Space Economy and Commerce

ESA HQ welcomes the 1st Edition of the ECSECO Space Economy...

ESA Space Economy – Partnering with Eurostat and the Europea...

ESA ARTES Partnership Projects, providing the satcom industr...

European Human Space Transportation: Technological, Social a...

Upcoming event: ECSECO Space Economy Days

EUSPA publishes the 2nd Issue of its EO and GNSS Market Repo...

The OECD publishes the 2nd Edition of its flagship publicati...

Space Forum for Green Energy, an upcoming event from the ESA...

ESPI publishes its annual report on the private investment i...

FutureEO, critical enabler of EO benefits for the European e...

The OECD publishes the 2nd Edition of the Handbook on Measur...

Terrae Novae: from inspiring Europe’s generations to support...

ESA TIA ARTES programme’s continuous boost to the commercial...

Exploiting the remarkable potential of space technology tran...

Technology developments for ESA science missions empowering...

ESA Space Economy Team presents a paper on “Statistic and th...

European Centre for Space Economy and Commerce (ECSECO) pres...

ESPI Yearbook 2021 – Space Policies, Issues, and Trends of t...

ESA Science Core Technology Development Success Story - Broa...

ESA Science Core Technology Development Success Story - Game...

ESA Science Core Technology Development Success Story - Grou...

ESA Science Core Technology Development Success Story - Fost...

ESA Science Core Technology Development Success Story - Crit...

ESA Science Core Technology Development Success Story - Unri...

ESA Science Core Technology Development Success Story - Firs...

ESA Technology Transfer Success Story - From space debris to...

ESA Technology Transfer Success Story - Dry electrodes to mo...

ESA Technology Transfer Success Story - Closing the loop: ho...

ESA Technology Transfer Success Story - Uncovering the secre...

ESA Technology Transfer Success Story - Landing zone assessm...

ESA Technology Transfer Success Story - Space at home: using...

Space-based Solar Power: Contributing to achieving Net Zero...

ESA Space Operations and Space Safety activities: supporting...

Europe decides to increase ESA’s budget by 17% compared to t...

European Centre for Space Economy and Commerce (ECSECO) conc...

Seven Benefit Case Studies of ESA's Space Safety programme

OECD Policy Paper: How the War in Ukraine is affecting Spac...

Beyond Borders: Satellite Applications for Humanitarian Emer...

“Earth’s Orbits at Risk”, 2022 OECD report on the Economics...

ESA Technology Transfer Success Story - The missing layer: h...

ESA Technology Transfer Success Story - Powering a village f...

ESA Technology Transfer Success Story - No such thing as a w...

“International Space Station (ISS) Benefits for Humanity”; 2...

Valuing the benefits of ESA Aeolus missions to European deci...

European Centre for Space Economy and Commerce (ECSECO) offi...

ESPI Space Venture 2021 – Entrepreneurship and Investment in...

ESPI Space Venture 2022 – Investment in the European and Glo...

ECSECO open for membership registration on its official webs...

ESA Centre to develop Europe’s Space Economy and promote com...

The OECD Space Forum launches second phase of research oppor...

EARSC showcasing Copernicus uses for Environmental Complianc...

Creation of the European Centre for Space Economy and Commer...

ESA-Eurostat workshop on a European Space Economy Satellite...

EUSPA publishes EO and GNSS Market Report 2022

BEA’s “Estimating the United States Space Economy Using Inpu...

The European Commission publishes the 2021 Edition of its Be...

ESPI Yearbook 2020 – Monitoring the development of the Europ...

ESA Technology Transfer Success Story - Using space heritage...

EARSC workshop showcasing 24 Copernicus Sentinel value case...

The Canadian Space Agency publishes the 2021 & 2022 State of...

OECD’s examination of Space Technology Transfers and their C...

PwC’s ‘Lunar market assessment: market trends and challenges...

ESA Technology Transfer Success Story - Space-style control...

ESA Technology Transfer Success Story - Cities as Spaceships...

ESA joins the Universeh inaugural conference to address the...

ESA announces winners of the Global Space Markets Challenge

SPAC and the Space Industry

G20 Space Economy Leaders Meeting 2021

Top 12 companies selected in Global Space Markets Challenge

Global Space Markets Challenge: Longlists announced

Measuring how space creates jobs and prosperity on Earth

The Size & Health of the UK Space industry in 2019

Copernicus Sentinel data supporting the pulp and paper indus...

Entrepreneurship and private investment trends in the Europe...

Global Space Markets Challenge Competition

Metalysis–ESA Grand Challenge: team Malt wins first phase

The International, North American and European Statistical C...

OECD’s approach to space sustainability and the economics of...

China’s Space Sector: Commercialisation with Chinese Charact...

Space Architecture: Economic impacts, future developments an...

ESA_Lab@UCLan: Assessing the public value of ESA programmes

Call for participants: OECD's initiative on the value and su...

Big Science in the 21st Century – a new e-book published by...

Financing SMEs: options for SMEs and Midcaps in Europe

The socio-economic value of satellite Earth observations: hu...

Copernicus Sentinel Data supporting wine making in France

ESA_Lab@Kozminski: A new bird in the nest of ESA_Lab

ESA_Lab@PoliBa: De’ remi facemmo ali

OECD's analysis of the impacts of Covid-19 on the Space indu...

Post-crisis scenarios for the space industry

Resilience of the space sector to the Covid-19 crisis

Financing space: options for SMEs and midcaps in Europe

Watch again the GSEW Online

Non-space business? We want to hear from you

Join the Third Online Global Space Economic Workshop

Join the Second Online Global Space Economic Workshop

Join the First Online Global Space Economic Workshop

Watch again the GSEF 19

Interview with Eric Morel de Westgaver on Europe's space eco...

Global Space Economic Forum: Space Creates Value

Kick off of Metalysis – ESA Grand Challenge: the Race to Min...

ESA at the New Space Economy European Expoforum

Advancing the understanding and measurement of the societal...

ESA Space Economy Brochure

Space cybersecurity for smart cities

Space workshops to power urban innovation

Building and powering by disruptive innovation

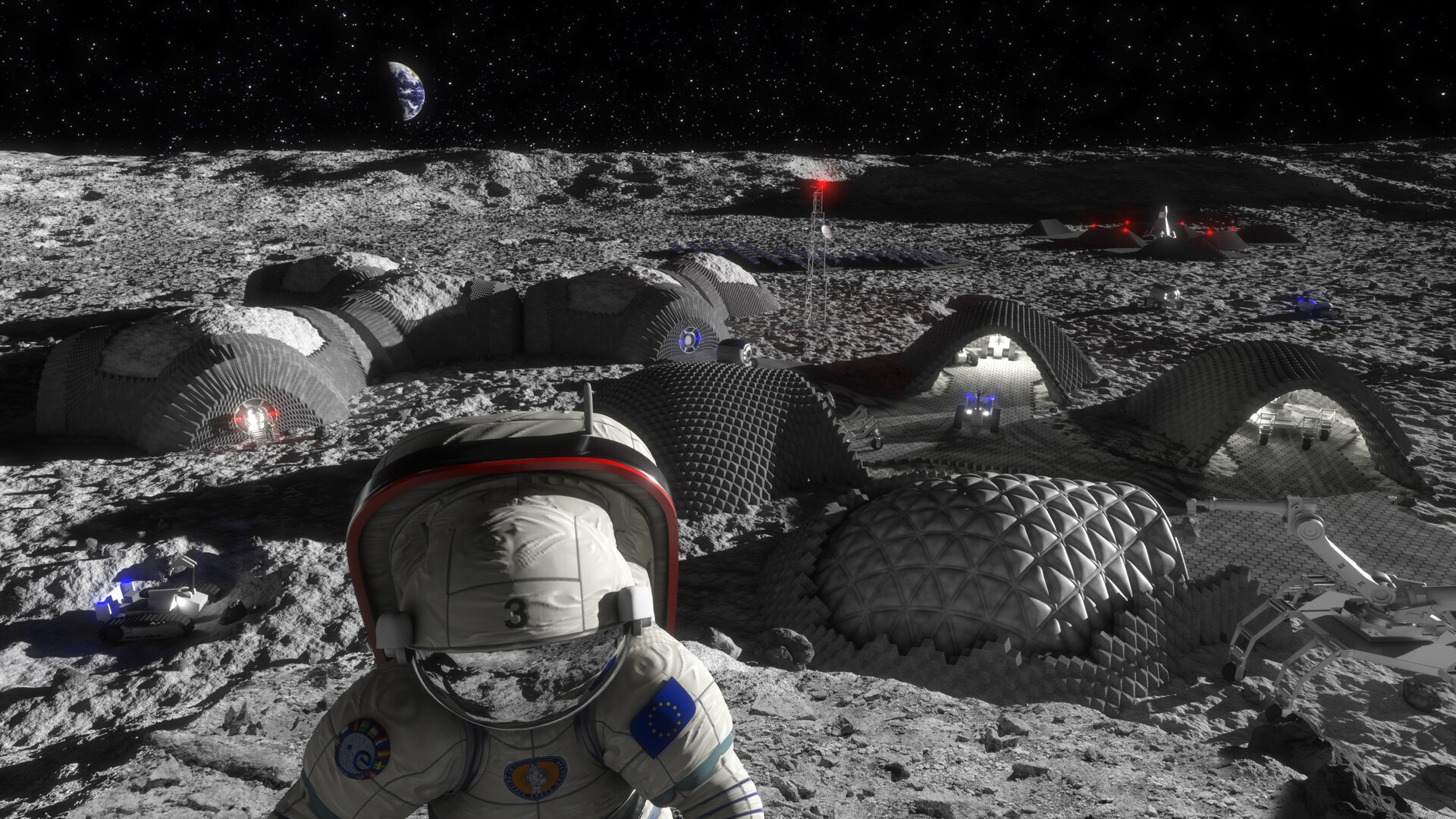

Challenges of future urban settlements on the Moon and Mars

ESA at the New Space Economy European Expoforum

Two Teams Competing for a Half-million Prize

Creating value

ESA and Metalysis decide to suspend temporarily the Grand Ch...

Value created by ESA Telecommunication Partnership Projects

Value created by ESA's Future Earth Observation Pillar

Value created by ESA Science Programme

Value created by ESA's Ground Systems Engineering and Operat...

The socio-economic impact of space activities

Measuring the Space Economy

Value created by ESA's Clean Space Initiative

The Covid Crisis: for European SMEs, this could be a breakth...

Why it is important to keep investing in space during and af...

What is the Space Economy?

A closer look at the latest Earth Observation Services Indus...

ESA Global Space Economic Forum

Welcome to the Global Space Economic Workshop

The benefits of Copernicus’ Sentinel data to society, enviro...

ESA announces first Global Space Economic Forum

Global Space Economic Workshop

Discussing solutions at the Global Space Economic Workshop

Building cybersecurity at the Global Space Economic Workshop

Global Space Economic Workshop

Interview with Vincent Bastide on construction

A closer look at OECD’s methodology for assessing the scient...

Interview with Guglielmo Baeli on the oil and gas sector

Interview with Giulia Pastorella on cybersecurity

Last chance to join the competition

OECD’s analysis of the impacts of Covid-19 on the space indu...

ESA at Station F: looking for applications to the first Gran...

Compete in a lunar economy

The Moon Race: Pioneering Sustainable Lunar Exploration

Value created by ESA's Space Systems for Safety and Security...

Metalysis–ESA Grand Challenge launched

A closer look at the European Commission’s Guide to Cost-Ben...

Value created by ESA's planetary defence initiative and Hera...

A community of innovation at the Farnborough Airshow and ESA

Join us at Le Bourget to discuss space for commercial purpos...

Game changers for the ESA Grand Challenge

Setting the stage

Fuel the future by joining the Innovation Exchange

ESA Grand Challenge rewards solutions to complex problems